University of Applied Sciences Magdeburg-Stendal, Germany

Our tasks in the project are closely related to material testing as base for further material development for the HEELLESS running shoe. Modern equipped labs as well as well highly trained and motivated staff are the pre-requirements for successful research.

Our present investigations for the HEELLESS project include:

- Investigation on the chemical components of composite materials

- Determination of the wetting behaviour of fibres/fabrics

- Testing of the breaking resistance of fabrics

- Improvement of the fibre-matrix-adhesion in composites

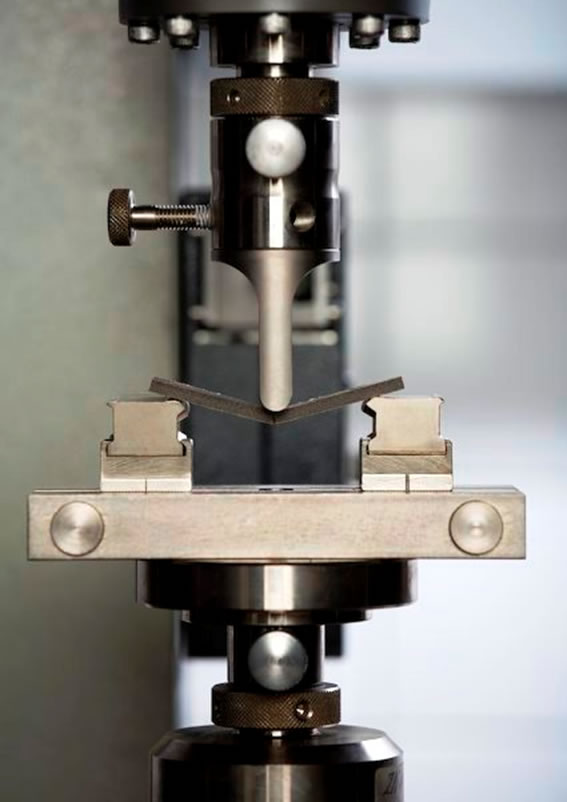

- Testing of mechanical properties of composites (tensile strength, flexural strength, interlaminar shear strength, impact strength)

New developed composite materials will play an important role to transfer the concept of heelless running into a running shoe.

The research we perform in the HEELLESS consortium can be classified into base-oriented investigations (chemical components, wetting behaviour, fibre-matrix-adhesion) and application-oriented measurements. Both kinds of investigation complement one other.

In the HEELLESS project the Centre of Competence performes basic investigations to characterise the wetting behaviour of fabrics.

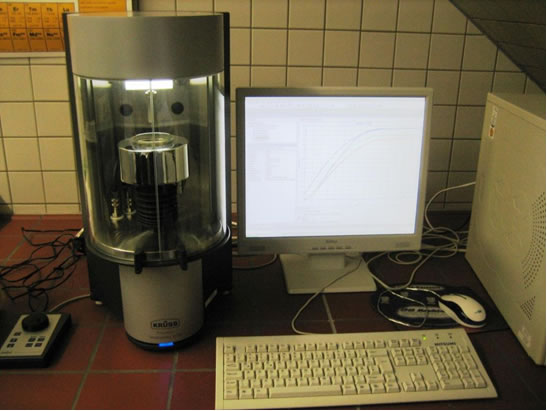

Processor tensiometer (wetting behaviour of fibres)

Fibre container

Base-oriented investigations

The Fourier transform infrared spectroscopy (FT-IR) is a method to get the chemical fingerprint of a material. Coupled with an IR-microscope it is possible to identify small particles or single components material mixtures.

FT-IR spectroscope coupled with an IR-microscope

A processor tensiometer is a universal instrument and suited for the determination of surface and interfacial tension, contact angles and surface energies. The knowledge of the surface tension of liquids (resins, polymer melts, glues) and free surface energy of solids (fibres, fabrics, polymers) are basic information for material and product developments.

Application-oriented investigations

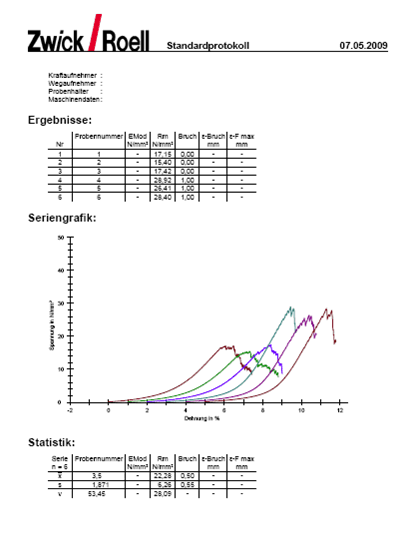

The determination of several mechanical properties leads to direct improvements of materials for the uppers and the sole. One example is the determination of the break resistance of fabrics. Textiles used in running shoes are subjected high mechanical stress. To guarantee a sufficient durability best suited fabrics have to be evaluated.

Fabric testing (break resistance)

Result of fabric testing

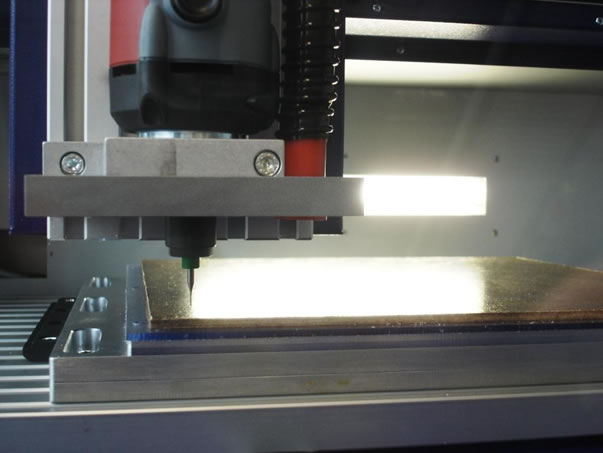

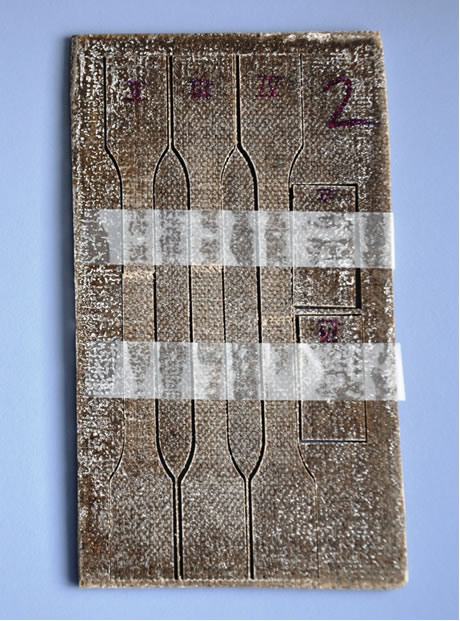

Modern running shoes contain several types of materials. Especially for the sole a complex and time-consuming development of new materials is required. Series of tests have to be performed to understand the material behaviour and to improve the properties.

CNC-controlled milling of test specimen

Specimen for mechanical testing

Allround testing machine for mechanical testing

Determination of flexural strength

University of Applied Sciences Magdeburg-Stendal, Germany

Research from University of Applied Sciences Magdeburg-Stendal, Germany

Download U Applied SCince Germany Research.doc (1,746.00kb)